Safeguard Your Structures, Investments & Workers with Height Safety Inspections

A large number of height safety assets are connected to the supporting structure with the use of rivets. Thorough inspection of these fixings is crucial in determining the assets’ structural capability. Rivet inspection is indispensable due to its profound impact on structures’ overall safety and stability. Rivets, although small, are instrumental in holding components together, making their integrity essential to maintain.

Height safety and rivet inspections in Melbourne are vital for various industries and businesses. This includes education facilities, retail precincts, construction companies, aged care facilities , , and manufacturing businesses.

If you are in Melbourne or surrounding areas, contact us for all your height safety inspection needs.

Two Primary Issues with Rivets

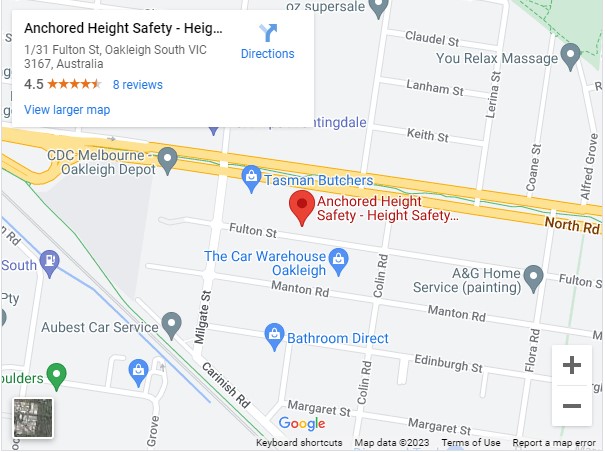

If a bulb-type rivet has not set correctly, , as evidenced by the stem snapping off too low ,insufficient strength of the fixing and may cause a catastrophic failure of the height safety asset

Another issue is the potential of water ingress due to the incorrect installation which may damage the building structure and contents.

How To Know If Rivets Were Installed Correctly:

It is especially essential to be vigilant when the rivet has a large hole, or the stem is snapped off at the base. Such a scenario signals a potential catastrophic failure, with the rivet failing to bulb out correctly. This fault is easily identifiable by observing where the stem protrudes; a missing stem is a red flag.

How To Identify if Rivets Were Incorrectly Installed:

NOTE – The root cause of this issue frequently stems from the ‘bulb’ being unable to expand as it comes into contact with the side of the roof sheet. To prevent this occurrence, the rivet must be placed centrally.

Remember, it’s crucial to check the rivets regularly. If you spot a dark hole in the rivet, as depicted in the attached image, replace it immediately. Ensure the riveter’s nose tip is correct for the 8mm bulb-type rivet. We have provided a downloadable document to reference causes and rectifications for rivet issues, and if you need our team to do a thorough inspection to ensure everyone’s safety, feel free to contact us.

The Dangers of Not Inspecting Rivets

Not inspecting rivets in workplaces or commercial buildings can lead to many potentially catastrophic consequences.

The Use of Go-No Go Gauge

The “go-no go” gauge is used to elucidate the 5mm pass criteria validation, which determines whether a workpiece meets the specified tolerances. A small amount of silicon seals the hole in rivets larger than 3mm but smaller than 5mm to prevent water penetration, thus maintaining the structure’s integrity.

For more information about rivet inspection and recertification, or if you’d like to request a quote, contact us today.

Benefits of Rivet Inspection

Rivet inspection offers numerous benefits to workplaces and establishments in Melbourne:

Anchored Height Safety

Our Trusted Clients