How Anchored Height Safety Revolutionised Documentation and Supercharged Efficiency with Bluebeam

The introduction of Bluebeam into Anchored Height Safety's operations spelled a significant turning point.

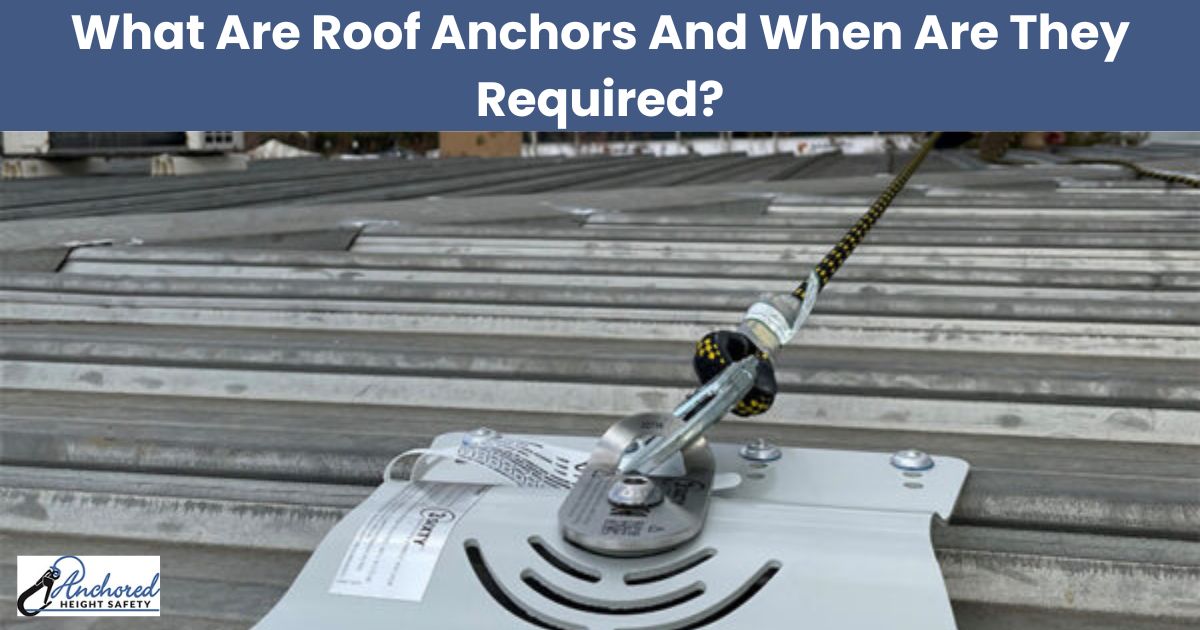

What Are Roof Anchors And When Are They Required?

If your business deals with working on a roof such as servicing air conditioners, gutters, or roof maintenance (or other roof related work), you know the dangers that go hand in hand with this type of work.

The 3 Most Important Safety Tips When Using Roof Anchors

Any time you have employees working at height, they are exposed to the possibility of experiencing slips and injuries. Though your schedule may be hectic, it’s your responsibility as a manager or supervisor or even a company owner to provide your employees with the necessary fall protection systems to safeguard their lives.

Avoiding Common Pitfalls With Height Safety Contractors

At Anchored Height Safety, we know that you need your service providers to have the right insurance as height safety installations and inspections involve a high level of risk. General ‘tradie’ insurance will not cover most works at height and typically specialised insurance will be required.

Height Safety – Always Our Top Priority

It’s no secret. Working at heights is very risky. Whether your team is painting a two-story roof or doing routine maintenance on a higher commercial structure, there’s always the risk of injury. The secret to getting on and off a high workspace comes down to two words – height safety.

Edge Protection Installation and Why Is It Important

Anchored received a call from the Council on behalf of the mechanical air-conditioning technicians they had contracted to work on [...]

10 Ways To Take Care Of Your Height Safety Equipment

How To Take Care Of Your Height Safety Equipment When it comes to protecting your workmen/employees on site, it’s important [...]

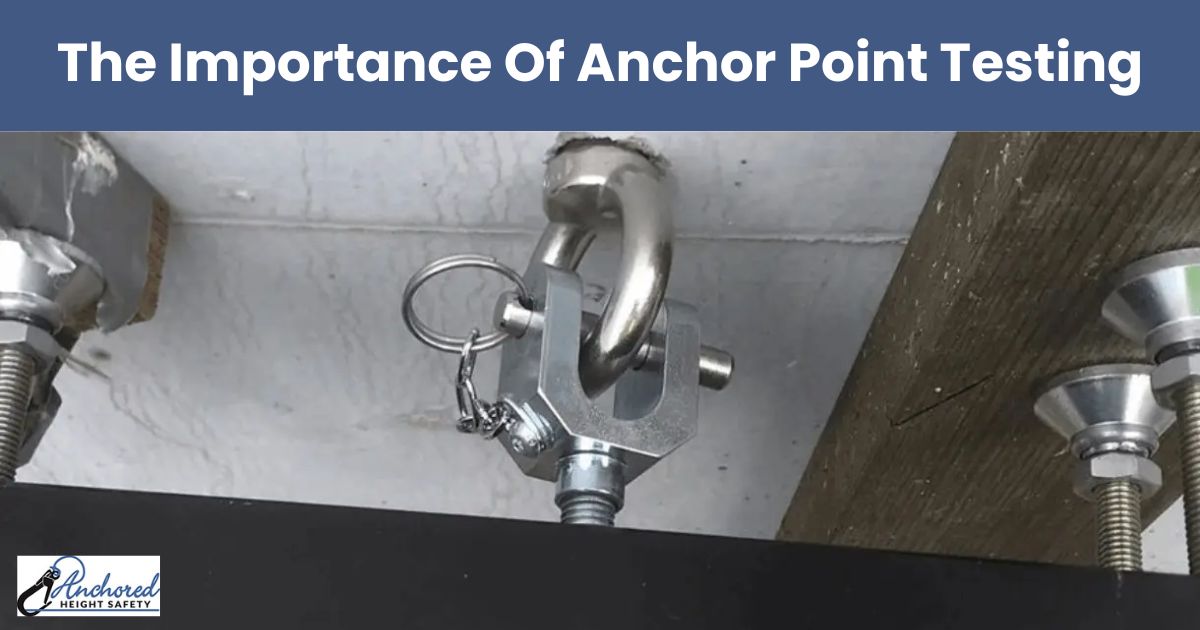

The Importance Of Anchor Point Testing

The views you get to see when working from heights can be an incredible perk of the job if you [...]